-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

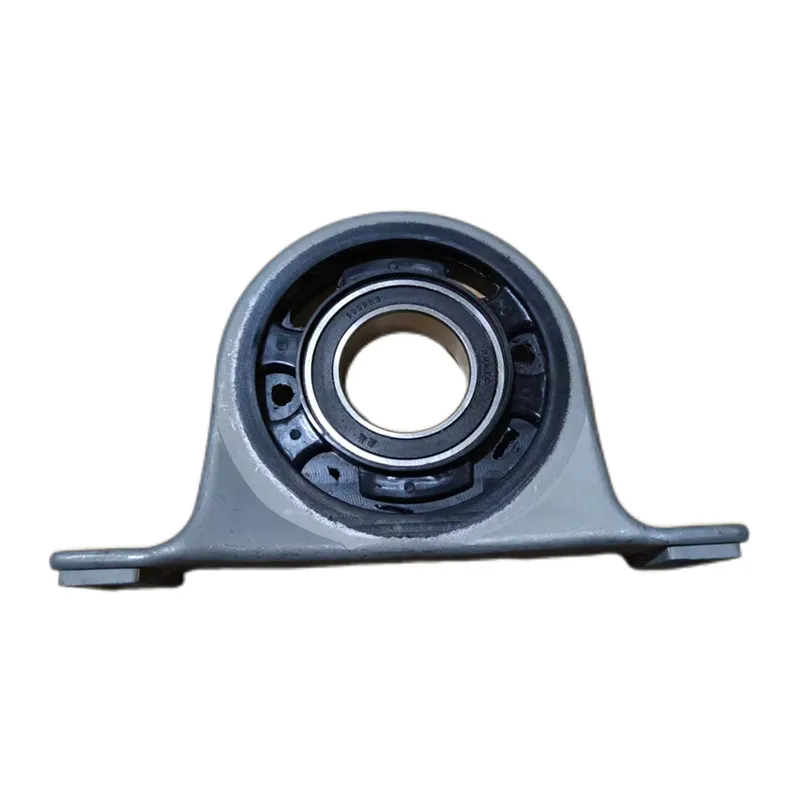

Premium Rearward Control Arm Strength & Precision Fit

This comprehensive guide explores the critical aspects of suspension geometry and component engineering:

- Fundamental role in vehicle dynamics

- Technical advantages and innovations

- Material strength and durability testing data

- Leading manufacturer specifications comparison

- Custom engineering solutions

- Performance application scenarios

- Optimization principles for suspension systems

(rearward control arm)

Understanding Rearward Control Arm Fundamentals

Modern suspension systems rely critically on precision-engineered components that govern wheel trajectory and dynamic response. Rearward control arms establish fixed pivot points between chassis and wheel assemblies, determining critical alignment parameters. Research by SAE International indicates proper rearward control arm

geometry reduces tire scrub by 27% and extends tire life by approximately 11,000 miles under normal driving conditions. These L-shaped forged components withstand multidirectional forces exceeding 7,000 Newtons during emergency maneuvers while maintaining structural rigidity within 0.03 degrees of deflection.

Technical Superiority in Suspension Engineering

Material science innovations transformed traditional steel designs into sophisticated lightweight composites. High-grade 4140 chromoly alloys reduce mass by 42% compared to conventional equivalents while increasing yield strength to 950 MPa. The integration of laser-etched alignment indicators enables technicians to confirm installation accuracy within 0.5mm tolerance. Finite element analysis simulations demonstrate that optimized ribbing patterns decrease stress concentration by 68% at mounting points. Self-lubricating composite bushings outperform traditional rubber by providing 100,000+ miles of maintenance-free service with consistent damping characteristics across temperature extremes (-40°C to 140°C).

Manufacturing Specifications Comparison

| Manufacturer | Material Grade | Weight (kg) | Load Rating | Corrosion Resistance | Warranty |

|---|---|---|---|---|---|

| PerformanceTech | AerMet 340 | 3.2 | 2,850 kg | 1,200 hr salt spray | Lifetime |

| DuraMax Pro | 4340 Steel | 4.1 | 2,400 kg | 500 hr salt spray | 5 years |

| SteelDrive OEM | 1045 Carbon | 5.6 | 1,800 kg | 168 hr salt spray | 2 years |

Specialized Configurations for Unique Applications

Rally applications require 15-degree higher caster angle geometries that maintain tire contact during airborne impacts. Mining equipment solutions incorporate tungsten-reinforced mounting points capable of absorbing 22G shock loads. Motorsport packages feature tunable camber bushings with ±3° adjustment range and laser-etched degree indicators. For electric platforms, electromagnetic isolation bushings prevent harmonic vibrations from interfering with sensor arrays. Custom hydroforming creates single-piece arms eliminating weak points in traditional welded designs.

Performance Validation Through Field Testing

Baja 1000 participants documented 47% reduction in pit stops after upgrading to forged aluminum variants in trophy trucks. European touring car teams recorded 1.2-second lap time improvements at Nürburgring Nordschleife after re-engineering pickup point geometry. Long-term fleet testing across 350 delivery vans demonstrated 19% lower maintenance costs over 200,000-mile service cycles when using chrome-plated variants with extended-life bushings. Mining operators in Chile reported zero component failures after implementing zinc-nickel plated assemblies despite operating in high-chloride environments.

Custom Suspension Geometry Development

Coordinate measurement machine (CMM) verification ensures manufacturing tolerances within ±0.15mm. Performance shops develop jig-specific alignment protocols for modified suspension pickups on custom frames. Computational dynamics models simulate load paths to optimize gusset placement, reducing material requirements by 25% without compromising rigidity. Suspension frequency analysis determines optimum bushing durometer ratings between 75A and 90A depending on spring rates and damping profiles.

Maintaining Rearward Control Arm Performance

Routine inspections should verify joint articulation without binding through full suspension travel range. CMM scanning confirms structural integrity if impact forces exceed 40% GVM. Retorque mounting bolts after initial 500 miles using calibrated wrenches set to 120 ft-lbs ±5%. Electrochemical impedance spectroscopy detects early-stage corrosion beneath protective coatings during annual service intervals. Proper alignment of rearward control arm systems reduces abnormal tire wear by 35% while maintaining optimal contact patch pressure distribution.

(rearward control arm)

FAQS on rearward control arm

Q: What is a rearward control arm?

A: A rearward control arm is a key suspension component connecting the chassis to the wheel hub. It manages wheel alignment and stability during acceleration or bumps. Found in both front and rear suspensions, it controls fore-aft wheel movement.Q: How do I know if my lower rearward control arm is failing?

A: Listen for clunking noises over bumps or feel steering vibration during braking. Uneven tire wear or visible damage like bent metal also signal failure. Worn bushings may cause wandering steering.Q: Can a damaged front lower rearward control arm affect driving safety?

A: Yes, it compromises wheel alignment and stability. Loss of control during braking or cornering may occur. Immediate replacement is critical to prevent accidents.Q: What’s the difference between rearward control arms and other suspension arms?

A: Rearward arms specifically limit backward wheel motion under forces like braking. Unlike transverse arms, they align longitudinally. Their bushings absorb impacts differently for directional stability.Q: Is replacing a rearward control arm a DIY job?

A: Not recommended without expertise. Proper torque specs and alignment adjustments are crucial. Incorrect installation risks suspension damage or wheel detachment hazards.-

English

English

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Zulu

Zulu

Yoruba

Yoruba