-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

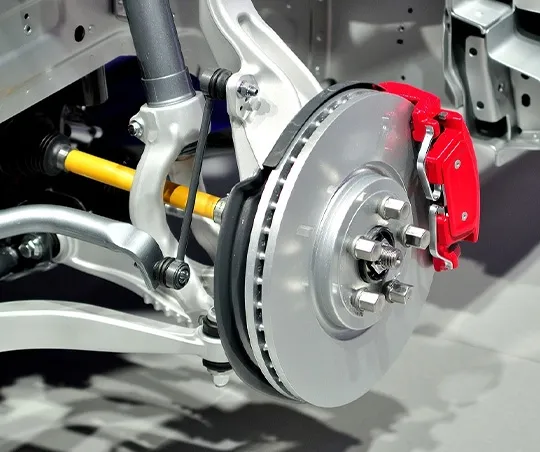

broken control arm

Understanding Broken Control Arms Causes, Symptoms, and Solutions

The control arm plays a crucial role in the suspension system of a vehicle. It serves as a link between the chassis and the wheels, allowing for controlled movement and ensuring stability while driving. When a control arm is broken, it can lead to severe complications and a significant compromise in vehicle safety and performance. Understanding the causes, symptoms, and solutions associated with a broken control arm is essential for any vehicle owner.

Causes of Broken Control Arms

Several factors can contribute to a broken control arm, including

1. Impact Damage One of the most common causes of control arm failure is damage from impact. This can occur from hitting potholes, curbs, or other road debris. Such impacts can bend or fracture the control arm, leading to misalignment and other issues.

2. Wear and Tear Over time, the control arm can degrade due to regular wear and tear. Components like bushings and ball joints can wear out, leading to increased stress on the control arm itself. Routine maintenance is essential to prevent this deterioration.

3. Corrosion Vehicles exposed to harsh weather conditions or road salt may experience corrosion. This degradation can weaken the control arm, making it more susceptible to breaking, especially if combined with other stress factors.

4. Poor Installation or Quality If control arms are not installed correctly or if subpar parts are used during a repair, it can result in premature failure. Therefore, it's vital to use quality replacement parts and have them installed by a qualified technician.

Symptoms of a Broken Control Arm

Recognizing the symptoms of a broken control arm can save you from more severe issues down the road

. Some common signs includebroken control arm

1. Unusual Noises A broken or damaged control arm often produces clunking or rattling noises, especially when going over bumps or making turns. These sounds are indicative of parts in the suspension system that are not functioning properly.

2. Poor Handling If your vehicle feels unstable or pulls to one side, it may be a sign of a broken control arm. The misalignment caused by a damaged arm can lead to difficulty steering and overall poor handling.

3. Uneven Tire Wear A failing control arm often leads to improper wheel alignment, resulting in uneven tire wear. If you notice that your tires are wearing down unevenly, it may be worth inspecting the control arms and suspension system.

4. Vibrations Excessive vibrations felt in the steering wheel or throughout the vehicle can also indicate a control arm issue. These vibrations may worsen during acceleration or when navigating turns.

Solutions for Broken Control Arms

When a broken control arm is diagnosed, prompt action is necessary to ensure safety and maintain vehicle performance. Here are some solutions

1. Inspection and Diagnosis If you suspect a broken control arm, the first step is to have your vehicle inspected by a qualified mechanic. They can accurately diagnose the issue and determine whether the control arm needs repair or replacement.

2. Replacement If the control arm is damaged beyond repair, replacement is often the best course of action. This may involve replacing just the control arm or, in some cases, the entire suspension assembly depending on the extent of the damage.

3. Regular Maintenance To prevent control arm issues, regular vehicle maintenance is crucial. This includes checking the suspension components during routine service intervals, ensuring proper alignment, and addressing any signs of wear immediately.

In conclusion, a broken control arm can significantly affect vehicle safety and performance. By understanding the causes and symptoms, drivers can take proactive steps to maintain their vehicles and address issues promptly. Regular inspections and maintenance are key to ensuring a safe and reliable driving experience.

-

English

English

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

Uighur

Uighur