-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 07, 2025 01:09

Back to list

control arm toyota

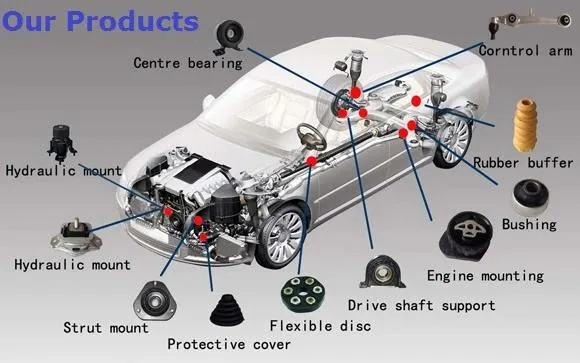

When discussing vehicles as renowned for reliability and innovation as those made by Toyota, even seemingly minor components, like control arms, play a crucial role in overall performance and safety. The control arm, a vital link connecting the wheels to the chassis, is engineered for precision and endurance. This piece aims to delve into the subject of Toyota control arms, focusing on their significance, variations, and maintenance, with insights reflecting a profound understanding of automotive dynamics and mechanical reliability.

Authoritativeness in the realm of automotive maintenance particularly emphasizes the regular inspection and timely replacement of control arms, a stance adopted widely within the Toyota owner community. It is advocated that control arm bushings, which cushion the arm from metal-on-metal contact, be monitored for signs of wear such as unusual noises or misalignment. Toyota's official service guidelines suggest rigorous checks at prescribed intervals, which substantiate the company's commitment to safety and integrity. Trustworthiness is further reinforced through Toyota’s provision of OEM (Original Equipment Manufacturer) control arms available through authorized dealerships and certified service centers. These parts assure compatibility and uphold the warranty stipulations, offering peace of mind to Toyota owners who desire assurance in every component. Moreover, online automotive forums and user groups serve as platforms where Toyota owners and car enthusiasts exchange information regarding the performance and replacement of control arms. These discussions often highlight success stories where routine maintenance of suspension systems, including control arm servicing, directly correlated with the extended lifespan and superior performance of their vehicles. In conclusion, Toyota control arms represent a small yet pivotal aspect of a vehicle’s architecture that embodies the brand's ethos of quality and reliability. For Toyota owners and enthusiasts seeking deeper knowledge, aligning mechanical insights with practical maintenance habits can enhance the driving experience significantly. By prioritizing OEM parts and adhering to expert recommendations on maintenance, one can ensure their Toyota delivers its promise of impeccable performance for years to come.

Authoritativeness in the realm of automotive maintenance particularly emphasizes the regular inspection and timely replacement of control arms, a stance adopted widely within the Toyota owner community. It is advocated that control arm bushings, which cushion the arm from metal-on-metal contact, be monitored for signs of wear such as unusual noises or misalignment. Toyota's official service guidelines suggest rigorous checks at prescribed intervals, which substantiate the company's commitment to safety and integrity. Trustworthiness is further reinforced through Toyota’s provision of OEM (Original Equipment Manufacturer) control arms available through authorized dealerships and certified service centers. These parts assure compatibility and uphold the warranty stipulations, offering peace of mind to Toyota owners who desire assurance in every component. Moreover, online automotive forums and user groups serve as platforms where Toyota owners and car enthusiasts exchange information regarding the performance and replacement of control arms. These discussions often highlight success stories where routine maintenance of suspension systems, including control arm servicing, directly correlated with the extended lifespan and superior performance of their vehicles. In conclusion, Toyota control arms represent a small yet pivotal aspect of a vehicle’s architecture that embodies the brand's ethos of quality and reliability. For Toyota owners and enthusiasts seeking deeper knowledge, aligning mechanical insights with practical maintenance habits can enhance the driving experience significantly. By prioritizing OEM parts and adhering to expert recommendations on maintenance, one can ensure their Toyota delivers its promise of impeccable performance for years to come.

Next:

Latest news

front-lower-control-arm-that-key-to-mitsubishi-lancer-or-outlander-suspension

NewsAug.22,2025

a-arm-car-components-that-premium-suspension-for-hyundai-santa-fe

NewsAug.22,2025

extended-control-arms-that-elevating-vehicle-suspension-performance

NewsAug.22,2025

essential-tools-for-driver-side-control-arm-replacement-procedures

NewsAug.22,2025

comprehensive-analysis-of-front-control-arm-and-front-upper-control-arm-technologies

NewsAug.22,2025

control-arm-that-reliable-automotive-components-by-hebei-lingke

NewsAug.22,2025