-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

පෙබ. . 15, 2025 15:42

Back to list

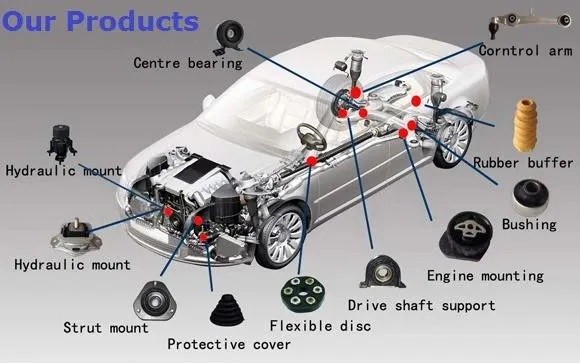

China manufacturer production center support bearing drive shaft bearing 9064100281 drive shaft support

Understanding the different types of control arms and their application in vehicle suspension systems is crucial for automotive enthusiasts, mechanics, and consumers seeking optimal performance and safety. Control arms, integral to a car's suspension system, connect the wheel hub and steering knuckles to the vehicle frame and allow for smooth, stable driving. This article seeks to provide a comprehensive look into the various types of control arms, their functionalities, and the best option for different vehicle needs.

Truck and SUV owners often find greater value in control arms specifically engineered for rugged and off-road conditions. Heavy-duty control arms, constructed with reinforced materials and designs, are intended to withstand robust and demanding terrains. These are often paired with high-grade bushings and ball joints geared towards greater endurance and less wear during off-road adventures. Selecting a heavy-duty control arm should take into account factors like vehicle weight and intended use, ensuring long-term durability and reliability. The choice of material in control arm construction significantly impacts their performance and longevity. Steel control arms, known for their strength and rigidity, are standard in many vehicles, ensuring resilient performance. However, they can be heavier, potentially impacting fuel efficiency. Alternatively, aluminum control arms offer lightweight solutions without sacrificing strength, contributing to better handling and efficiency. In high-performance applications, some manufacturers utilize composite materials, which combine the benefits of strength, flexibility, and reduced weight. When choosing control arms, factors like vehicle type, driving conditions, and maintenance preferences should guide decisions. Installation ease and accessibility to replacement parts also play critical roles in selecting the right control arm type. Ensuring that control arms are compatible with existing suspension systems and meet vehicular requirements is vital to optimizing vehicle performance and driver safety. In summary, understanding the various types of control arms available, from wishbone and MacPherson struts to multi-link and heavy-duty configurations, allows consumers to make informed decisions that enhance vehicle performance and safety. Material considerations—whether steel, aluminum, or composite—along with installation and maintenance aspects, must align with individual needs and preferences. By focusing on these factors, drivers can significantly improve their driving experiences and vehicle longevity, ensuring optimum vehicular performance tailored to specific demands.

Truck and SUV owners often find greater value in control arms specifically engineered for rugged and off-road conditions. Heavy-duty control arms, constructed with reinforced materials and designs, are intended to withstand robust and demanding terrains. These are often paired with high-grade bushings and ball joints geared towards greater endurance and less wear during off-road adventures. Selecting a heavy-duty control arm should take into account factors like vehicle weight and intended use, ensuring long-term durability and reliability. The choice of material in control arm construction significantly impacts their performance and longevity. Steel control arms, known for their strength and rigidity, are standard in many vehicles, ensuring resilient performance. However, they can be heavier, potentially impacting fuel efficiency. Alternatively, aluminum control arms offer lightweight solutions without sacrificing strength, contributing to better handling and efficiency. In high-performance applications, some manufacturers utilize composite materials, which combine the benefits of strength, flexibility, and reduced weight. When choosing control arms, factors like vehicle type, driving conditions, and maintenance preferences should guide decisions. Installation ease and accessibility to replacement parts also play critical roles in selecting the right control arm type. Ensuring that control arms are compatible with existing suspension systems and meet vehicular requirements is vital to optimizing vehicle performance and driver safety. In summary, understanding the various types of control arms available, from wishbone and MacPherson struts to multi-link and heavy-duty configurations, allows consumers to make informed decisions that enhance vehicle performance and safety. Material considerations—whether steel, aluminum, or composite—along with installation and maintenance aspects, must align with individual needs and preferences. By focusing on these factors, drivers can significantly improve their driving experiences and vehicle longevity, ensuring optimum vehicular performance tailored to specific demands.

Latest news

Understanding the Broken Control Arm: Key Insights for Car Owners

NewsJun.20,2025

The Essential Guide to Control Arms for Cars

NewsJun.20,2025

Discover Quality Control Arms for Your Vehicle

NewsJun.20,2025

Control Arm: Enhance Your Vehicle's Performance with Quality Parts

NewsJun.20,2025

Billet Control Arms: Elevating Your Suspension System

NewsJun.20,2025

Bent Control Arm: Understanding the Importance and Cost Implications

NewsJun.20,2025

-

English

English

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

Sinhala

Sinhala