-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

upper lower control arms

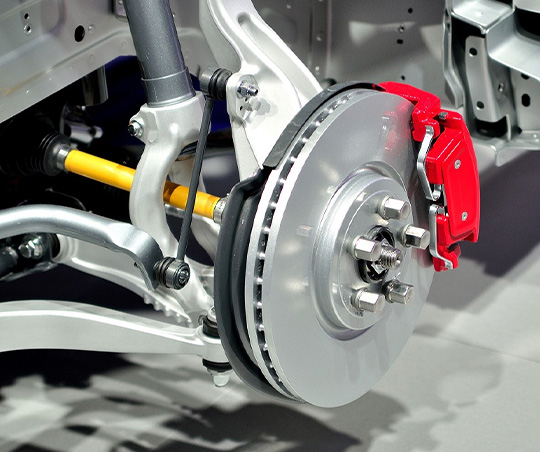

Understanding Upper and Lower Control Arms in Automotive Suspension Systems

In the realm of automotive engineering, the suspension system plays a vital role in vehicle performance, safety, and comfort. Among the critical components of this system are the upper and lower control arms. These components are essential in connecting the wheels of a vehicle to its chassis, allowing for precise control of wheel movement and stability during driving. This article explores the function, design, and importance of upper and lower control arms in automotive suspension.

Defining Control Arms

Control arms are lever-like components that are pivotal in a vehicle's suspension setup. They come in pairs—upper control arms and lower control arms—each serving distinct functions while working in tandem to manage the dynamics of the wheels. The upper control arm is typically shorter and connects the top of the wheel assembly to the vehicle's frame, while the lower control arm is generally longer, attaching the bottom of the wheel assembly to the chassis.

Functionality of Control Arms

The primary role of control arms is to maintain proper wheel alignment as the vehicle moves over uneven terrain. They allow for up and down motion of the wheels, facilitating the absorption of shocks and vibrations from the road. This movement is crucial for maintaining tire contact with the ground, which directly affects handling and braking performance.

In essence, while the lower control arm supports most of the weight of the vehicle and deals with the forces exerted by the road, the upper control arm serves to stabilize the wheel's positioning, particularly during cornering and when navigating bumps. This cohesive function allows for better steering response and overall vehicle stability.

Design Variations

upper lower control arms

Control arms come in various designs, primarily differing by the vehicles' needs and manufacturers' specifications. Common designs include A-frame (or wishbone), straight, and multi-link configurations. The choice of design impacts the handling characteristics and adaptability of the vehicle.

For example, A-frame control arms offer a combination of strength and lightweight, making them popular in sports cars for enhanced performance. Conversely, a multi-link suspension allows for greater adjustability and can improve ride comfort by better managing the angles of the wheels as they move.

Materials and Durability

The materials used in the construction of control arms are crucial for their performance and longevity. Typically, control arms are made from high-strength steel or aluminum. Steel offers durability and strength, making it ideal for heavy-duty applications, whereas aluminum is lighter, improving overall vehicle agility and fuel efficiency.

The choice of materials also affects the cost and maintenance of the vehicle. While aluminum control arms might come at a premium, their weight savings can translate to better fuel efficiency and performance—benefits that often justify the investment.

Importance and Maintenance

The importance of upper and lower control arms cannot be overstated. They are integral to ensuring a vehicle’s suspension system operates smoothly, thereby affecting all aspects of driving. Over time, wear and tear can impact their functionality, often resulting in symptoms such as uneven tire wear, poor handling, or a misaligned steering wheel. Regular maintenance checks can help identify any issues early, preventing more extensive repairs and ensuring the vehicle remains safe and responsive to driver input.

In conclusion, upper and lower control arms are pivotal components of an automotive suspension system, integral to vehicle safety, stability, and performance. Understanding their functionality, design variations, and maintenance requirements can aid vehicle owners and enthusiasts in appreciating the intricate engineering that contributes to a smooth and reliable driving experience. As vehicles continue to evolve, advancements in control arm technology will undoubtedly enhance the performance and comfort of modern automobiles.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English