-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

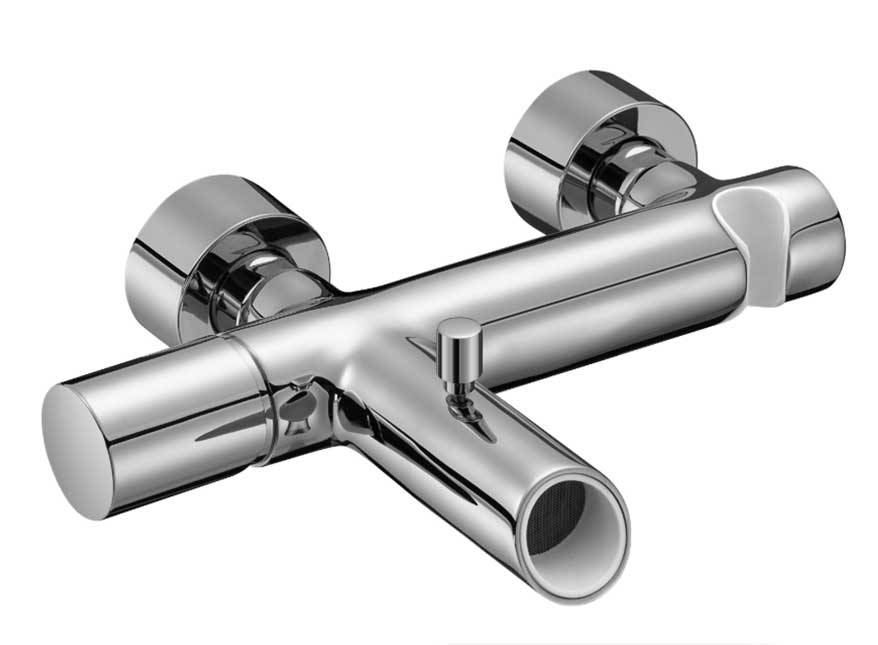

toyota lower arm

The Importance of Toyota Lower Arms Enhancing Vehicle Performance and Safety

When it comes to automotive engineering, every component plays a crucial role in the overall performance and safety of the vehicle. One such essential component belonging to the suspension system is the lower arm, specifically designed for various Toyota models. The lower arm, or control arm, is a pivotal part of a vehicle’s suspension that connects the wheel hub and steering knuckle to the chassis, allowing for controlled wheel movement while maintaining the structural integrity of the vehicle.

Understanding the Function of Lower Arms

The primary role of the lower arm is to stabilize the wheel during movement. It allows the wheels to move up and down while keeping them aligned with the body of the vehicle. This function is essential for achieving optimal handling, ride comfort, and tire wear. When a vehicle encounters bumps or uneven surfaces, the lower arm absorbs the shock, ensuring that the wheels maintain contact with the road. This not only improves traction but also enhances overall driving safety.

Material and Design Considerations

Toyota engineers take careful consideration regarding the materials and designs used for their lower arms. Typically, lower arms are made from high-strength steel or aluminum alloys, chosen for their durability and lightweight properties. While steel provides additional strength and resistance to deformation, aluminum offers an advantage in weight reduction, contributing to improved fuel efficiency.

Moreover, the design of the lower arm often includes features such as bushings and ball joints, which allow for rotational movement while absorbing vibrations. Toyota’s engineering team thoroughly tests different designs to balance performance and comfort, ensuring that each model provides the best possible ride quality to its drivers.

Common Issues and Maintenance

toyota lower arm

Like all vehicle components, the lower arms can experience wear and tear over time. Common signs of lower arm issues include poor handling, unusual tire wear, or strange noises when driving over bumps. If a lower arm is damaged or worn out, it can adversely affect the vehicle’s alignment and handling characteristics, posing potential safety risks.

Regular maintenance is crucial for ensuring the longevity and functionality of the lower arms. Toyota recommends routine inspections as part of the standard maintenance schedule. Drivers should be attentive to any signs of deterioration or performance loss and seek professional assistance at the first sign of trouble. Replacement of worn components can restore the vehicle’s handling and safety features.

Upgrading Lower Arms

For automotive enthusiasts, upgrading to aftermarket lower arms can be an attractive option. These upgraded components can offer enhanced performance advantages, such as improved stiffness and better handling characteristics. Many aftermarket manufacturers produce lower arms tailored for race or off-road applications, allowing drivers to modify their vehicles for specific driving experiences.

However, it is important to choose reputable brands and pay attention to compatibility with the vehicle model. Installing non-compatible parts can lead to further complications, including misalignment and even damage to other suspension components.

Conclusion

The lower arm is a vital component of Toyota's suspension system, playing a significant role in vehicle performance, safety, and comfort. Whether it is in standard daily driving or high-performance applications, the importance of maintaining and upgrading this component cannot be overstated. As vehicles continue to evolve, the innovations implemented in lower arm design and materials will undeniably contribute to driving experiences that are safer, more efficient, and enjoyable for all. Regular maintenance and timely upgrades can ensure that your Toyota remains in peak condition, providing an optimal driving experience on every journey.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English