-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

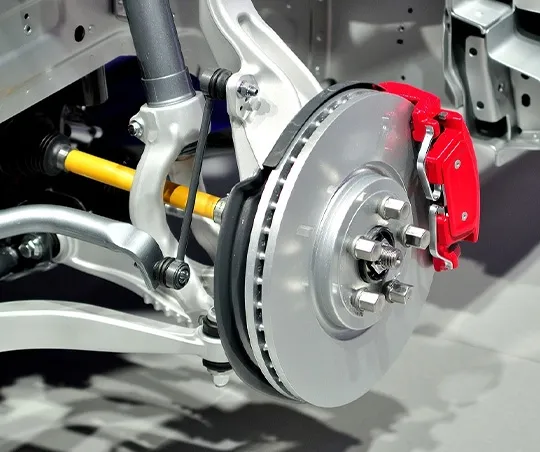

replacing lower control arm

Replacing Lower Control Arm A Comprehensive Guide

The lower control arm is a crucial component of your vehicle's suspension system, playing an essential role in handling and stability. Over time, due to wear and tear or damage from road conditions, the lower control arm may need to be replaced. Understanding the importance of this component and the steps involved in its replacement can help you maintain your vehicle's performance and safety.

What is the Lower Control Arm?

The lower control arm is a part of the suspension that connects the chassis of the vehicle to the wheel assembly. It allows for vertical movement while maintaining proper alignment of the wheels. The design can vary between vehicles, but the primary function remains the same it absorbs shocks from the road and helps to keep the tires in contact with the surface, providing stability and control during driving.

Signs You Need to Replace the Lower Control Arm

There are several signs that may indicate it's time to replace your lower control arm

1. Unusual Noises If you hear clunking or knocking sounds while driving, particularly over bumps or uneven surfaces, it could indicate that the control arm or its bushings are worn out.

2. Steering Issues A loose or unresponsive steering feel can suggest that the control arm is compromised. This can lead to instability while driving, increasing the risk of accidents.

3. Uneven Tire Wear If you notice uneven or excessive wear on your tires, it could be a sign that the alignment is off, potentially due to a failing control arm.

4. Vibrations Excessive vibrations in the steering wheel while driving can also signal issues with the suspension components, including the lower control arm.

The Replacement Process

replacing lower control arm

Replacing a lower control arm can be a complex procedure, but it can be done with the right tools and knowledge

. Here’s a simplified guide to the replacement process1. Gather Tools and Parts Ensure you have all necessary tools such as a jack, jack stands, wrenches, and a torque wrench. You'll need a new lower control arm along with new bushings and bolts.

2. Lift the Vehicle Safely raise the vehicle using a jack and secure it with jack stands. Always follow safety protocols to prevent accidents.

3. Remove the Wheel Take off the wheel on the side where you are replacing the control arm. This will provide access to the suspension components.

4. Disconnect Components You will need to disconnect several components to remove the lower control arm, including sway bar links and the ball joint. Labeling parts as you go can help during reinstallation.

5. Remove the Control Arm Once everything is disconnected, remove the bolts holding the lower control arm in place. Carefully lower the arm from its position.

6. Install the New Control Arm Align the new lower control arm with the mounting points and secure it with the new bolts. Make sure to torque the bolts to the manufacturer’s specifications.

7. Reattach Components Reconnect any components that were disconnected, including the ball joint and sway bar links. Ensure that everything is tightened to the proper specifications to avoid future issues.

8. Reinstall the Wheel Place the wheel back on and secure the lug nuts. Once everything is complete, lower the vehicle back to the ground.

Final Thoughts

Replacing the lower control arm is imperative for maintaining vehicle safety and performance. While the process may seem daunting, with proper tools and a methodical approach, it can be accomplished. If at any point you feel unsure or overwhelmed, don't hesitate to consult a professional mechanic. Regular inspections and maintenance of your vehicle’s suspension system are key to ensuring a safe and smooth driving experience. By keeping an eye out for warning signs and addressing them promptly, you can extend the life of your vehicle's components and enhance its overall performance.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English