-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

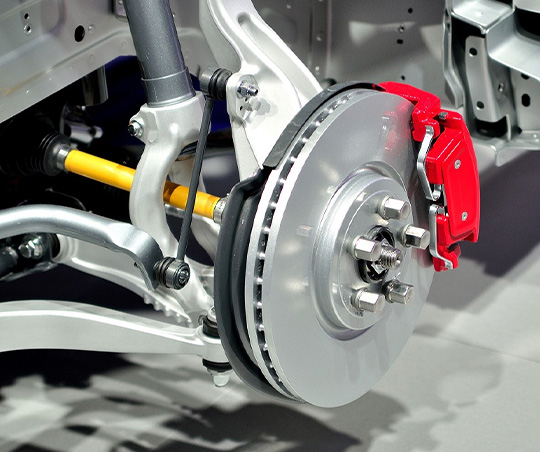

lower suspension control arm

Understanding Lower Suspension Control Arms in Automotive Design

The suspension system of a vehicle plays a crucial role in ensuring a smooth and stable ride. Among the many components that contribute to this system, the lower suspension control arm stands out as a vital element. This article will delve into the importance, functionality, design, and maintenance of lower suspension control arms, shedding light on their significance in automotive engineering.

What is a Lower Suspension Control Arm?

The lower suspension control arm is a component of a vehicle's suspension system, connecting the chassis to the wheel hub. Typically, it operates in conjunction with the upper control arm, forming a crucial part of the suspension geometry. This component primarily serves to guide the wheel's movement while maintaining the vehicle's stability during various driving conditions.

Functionality

The lower control arm plays a significant role in allowing the wheel to move vertically while controlling the lateral positioning. This vertical movement is essential for absorbing shocks from road irregularities, providing a smoother ride. The control arm's design facilitates the wheel's ability to articulate efficiently, allowing for better traction and handling, especially during cornering. Additionally, the control arm contributes to maintaining proper wheel alignment, which is critical for tire longevity and overall vehicle performance.

Design Considerations

Lower control arms are typically made from materials like steel, aluminum, or composite materials, chosen for their strength and weight characteristics. The design must account for various forces and moments generated during driving. Engineers carefully calculate dimensions and mounting points, ensuring that the control arm can withstand stress without deforming.

lower suspension control arm

An important aspect of control arm design is its geometry; the angle and length of the arm can significantly impact vehicle dynamics. For instance, altering the control arm's length or angle can affect the vehicle's camber and caster angles, impacting tire wear and handling characteristics. Therefore, the design process of a lower suspension control arm requires a deep understanding of physics and automotive dynamics.

Maintenance and Troubleshooting

Like any component in a vehicle, lower suspension control arms can experience wear and tear over time. Common signs of control arm issues include uneven tire wear, steering misalignment, and noticeable vibrations during driving. If drivers notice these symptoms, it may indicate the need for a thorough inspection.

Regular maintenance is crucial for the longevity of the control arm. This includes checking for any signs of rust, corrosion, or physical damage. The bushings—rubber or polyurethane components that cushion the connection between the control arm and the chassis—should also be inspected regularly, as worn bushings can introduce unwanted noise and affect handling.

Additionally, if a vehicle undergoes modifications, such as lowering or lifting, realignment of the control arms may be necessary to ensure optimal performance. Proper adjustment guarantees that the wheel alignment is within the manufacturer’s specifications, enhancing safety and drivability.

Conclusion

The lower suspension control arm is an integral part of vehicle suspension systems, influencing ride quality, handling, and safety. Its design and maintenance are crucial for ensuring that a vehicle performs optimally. Understanding the role of this component can empower vehicle owners and enthusiasts to care for their cars better, leading to improved safety and driving experience. As automotive technology continues to evolve, the materials and designs for lower control arms will likely advance, offering even better performance and durability for future vehicles.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English