-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Understanding the Function and Importance of Lateral Control Arms in Vehicle Performance

Understanding Lateral Control Arms The Unsung Heroes of Vehicle Suspension Systems

When it comes to automotive engineering, the focus often centers on engine performance, fuel efficiency, and sleek design. However, one critical component that significantly affects handling, safety, and ride quality is often overlooked the lateral control arm. This article aims to shed light on lateral control arms, their importance in vehicle suspension systems, and the advancements in their design.

What is a Lateral Control Arm?

A lateral control arm is a key component of a vehicle's suspension system, specifically designed to manage lateral forces during driving. These arms connect the vehicle's chassis to the wheel assembly, allowing for left and right movement while keeping the wheels aligned. This is crucial for maintaining stability, especially when cornering or making sudden directional changes.

The Role of Lateral Control Arms in Vehicle Dynamics

Lateral control arms play a pivotal role in a vehicle's overall dynamics. When a vehicle takes a corner, the lateral control arms help keep the wheels in contact with the road, allowing for better grip and handling. They also reduce body roll, which can greatly enhance passenger comfort and promote a safer driving experience. Additionally, these arms help prevent misalignment of the wheels, which can lead to uneven tire wear and negatively impact fuel efficiency.

Types of Lateral Control Arms

Lateral control arms typically come in several configurations, including

1. Single Control Arm Found in simpler suspension setups, this design offers basic lateral support but may not cope well with extreme cornering forces. 2. Double Control Arm (or A-arms) This design features two arms that create a triangular shape, providing a more stable and responsive suspension. This configuration is commonly found in performance vehicles and provides better handling characteristics.

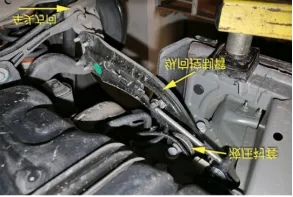

lateral control arm

Materials and Design Innovations

The traditional materials used for lateral control arms include steel and aluminum, but recent advancements have seen the introduction of materials like carbon fiber and high-strength composites. These materials offer an excellent strength-to-weight ratio, improving performance while reducing overall vehicle weight.

Design innovations also focus on geometry. Engineers are continuously refining the angles and lengths of lateral control arms to optimize vehicle handling. Adjustable control arms are another recent trend, allowing customization of suspension settings to suit different driving conditions or personal preferences—be it for daily driving, off-roading, or racing.

Maintenance and Durability

Lateral control arms endure significant stress over time, leading to wear and tear. Common issues include bushing degradation and cracks in the arms themselves. Regular maintenance checks are essential for ensuring the integrity of these components. Signs that a lateral control arm may need replacement include uneven tire wear, poor steering response, and unusual noises when turning.

Moreover, the durability of lateral control arms is crucial. High-quality materials and coatings can significantly extend the lifespan of these components, making it vital for vehicle owners to opt for parts that meet or exceed OEM specifications.

Conclusion

Lateral control arms are essential for safe and effective vehicle operation, yet they often remain hidden from view and overlooked by drivers. Understanding the vital role these components play can help car enthusiasts appreciate the complexities of automotive engineering. As innovations continue to evolve, lateral control arms will undoubtedly play a central role in the future of vehicle design and performance.

In essence, while the engine may provide power, it is the meticulous orchestration of components like lateral control arms that allows a vehicle to harness that power effectively, ensuring a safe and enjoyable driving experience. As technology advances, the importance of these unsung heroes in creating modern vehicles will only continue to grow.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English