-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

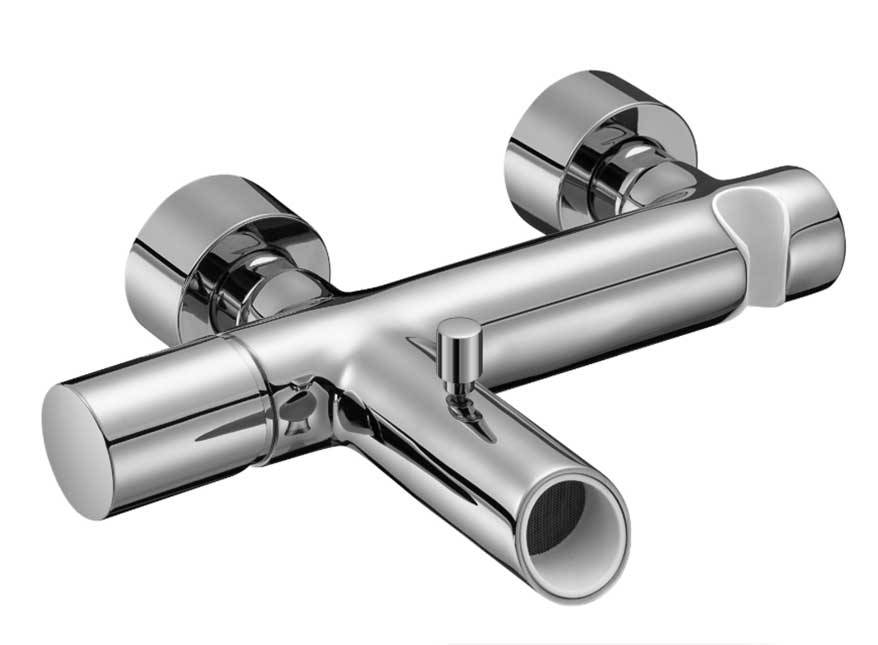

front lower forward control arm

Understanding Front Lower Forward Control Arms Key Components in Vehicle Suspension

When it comes to vehicle suspension systems, the front lower forward control arm plays a crucial role in ensuring the stability, handling, and safety of a vehicle. These components, often referred to simply as control arms, are integral to the suspension architecture, providing the necessary linkage between the vehicle's chassis and its wheels. In this article, we will explore the functions, types, and importance of front lower forward control arms in automotive engineering.

What Are Control Arms?

Control arms are hinged links that connect the vehicle's suspension system to the chassis. They are responsible for managing the relative motion between these two critical components, allowing for smooth wheel movement while providing stability. The front lower forward control arm specifically refers to those that are positioned at the front of the vehicle, supporting the lower section of the suspension system and connecting to the chassis in a forward position relative to the wheels.

Functions of Front Lower Forward Control Arms

1. Wheel Alignment and Stability One of the primary functions of front lower forward control arms is to maintain proper wheel alignment. By keeping the wheels in alignment with the chassis, these arms help ensure that the vehicle drives straight, improves handling, and reduces tire wear.

2. Load Distribution Control arms also play a vital role in load distribution across the suspension system. During cornering, braking, and acceleration, they help manage the forces acting on the wheels, ensuring even distribution of loads and preventing excessive strain on individual components.

3. Vibration Dampening Another important function of control arms is to dampen vibrations. The materials used in control arms, such as rubber bushings, help absorb shocks from road irregularities, improving ride comfort and reducing noise inside the cabin.

4. Allowing Suspension Travel Front lower forward control arms enable suspension travel, allowing the wheels to move up and down independently of the chassis. This movement is essential for maintaining traction and performance on varied road surfaces.

front lower forward control arm

Types of Control Arms

Control arms come in various designs, with the most common being

- Stamped Steel Control Arms These are typically less expensive and are widely used in standard vehicles. They offer good strength but may have limitations in terms of performance.

- Aluminum Control Arms More advanced vehicles often use aluminum control arms. They are lighter and provide better performance, though they can be more expensive to manufacture.

- Adjustable Control Arms Performance-oriented vehicles may feature adjustable control arms, allowing for fine-tuning of wheel alignment settings for optimal handling characteristics.

The Importance of Regular Maintenance

The front lower forward control arms are subject to wear and tear over time, particularly due to road conditions and driving behavior. Regular inspection and maintenance are essential to ensure these components remain functional and safe. Signs of wear may include unusual tire wear patterns, clunking noises during turns, or changes in handling. Replacing worn control arms promptly can prevent further damage to the suspension and improve overall vehicle safety.

Conclusion

In summary, the front lower forward control arm is a critical element of a vehicle's suspension system, playing a significant role in ensuring stability, comfort, and safety. Understanding their function and importance in your vehicle can help in recognizing signs of wear and ensuring proper maintenance. As automotive technology continues to evolve, the design and materials used in control arms are likely to advance, further enhancing vehicle performance and ride quality.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English