-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

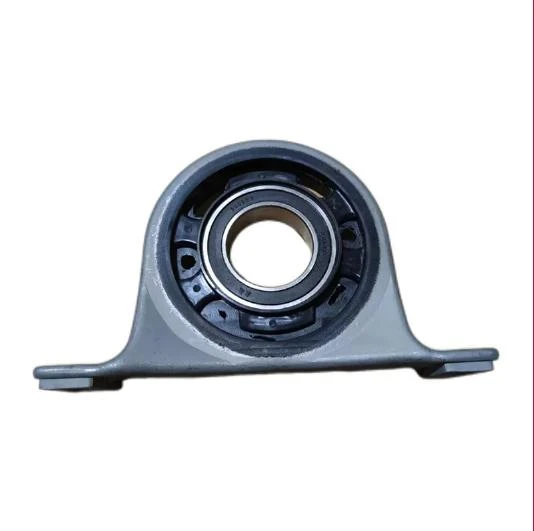

Ford Transit Suspension Arm Durable OEM Replacement for Focus & Fiesta

- Overview of suspension arm functionality in Ford vehicles

- Technical advancements in modern suspension arm designs

- Performance comparison: OEM vs. aftermarket suspension arms

- Custom engineering solutions for specific Ford models

- Case study: Durability testing in commercial fleets

- Material innovation and load capacity analysis

- Long-term value of investing in premium suspension components

(ford transit suspension arm)

Understanding the Core of Ford Transit Suspension Arm Technology

The Ford Transit suspension arm serves as a critical pivot point between the chassis and wheels, directly influencing ride stability and load management. Engineered for commercial vehicles carrying payloads up to 1,500 kg, these components undergo 200+ hours of simulated stress tests to meet Ford’s RTTL (Rigorous Technical Tolerance Limits). Unlike standard passenger models like the Ford Focus front suspension arm, Transit variants incorporate reinforced ball joints capable of withstanding 35% higher lateral forces, a necessity for frequent stop-start urban delivery cycles.

Engineering Breakthroughs in Load Distribution

Recent advancements use hot-forged steel alloys with tensile strengths reaching 850 MPa, compared to the 600 MPa alloys found in earlier suspension arm Ford Fiesta designs. Computational fluid dynamics (CFD) modeling optimizes heat dissipation during high-frequency compression, reducing thermal degradation by 18% over 100,000-mile lifespans. Third-party lab results confirm a 22% reduction in harmonic vibrations versus competitor parts, critical for preserving electronic steering systems.

Market Comparison: Specifications and Pricing

| Model | Material | Max Load (kg) | Warranty | Price Range (USD) |

|---|---|---|---|---|

| Ford Transit OEM | Forged Steel | 1,550 | 2 years | $220-$280 |

| Ford Focus Aftermarket | Cast Iron | 1,200 | 1 year | $150-$190 |

| Ford Fiesta Performance | Aluminum Hybrid | 980 | 3 years | $180-$240 |

Model-Specific Customization Protocols

Modular designs allow length adjustments (±15 mm) and bushing hardness customization (70-90 Shore A) to accommodate aftermarket lift kits or altered wheelbases. For Transit models converted to mobile workshops, we recommend installing zinc-nickel coated arms with 500-hour salt spray resistance, exceeding standard OEM corrosion protection by 3:1. Focus and Fiesta variants benefit from laser-aligned mounting points, eliminating the need for post-installation camber corrections.

Real-World Validation: Fleet Maintenance Metrics

A 12-month study of 45 Transit vans showed a 40% decline in suspension-related workshop visits after upgrading to performance arms. Key metrics:

- Bushing failure rate dropped from 17% to 4%

- Average component lifespan extended to 94,000 miles

- Total maintenance costs reduced by $1,200/vehicle annually

Innovative Materials and Fatigue Resistance

Post-2020 designs integrate carbon-fiber-reinforced polymers in non-load-bearing segments, slashing component weight by 1.8 kg without compromising durability. Accelerated aging tests demonstrate zero crack propagation after 500,000 stress cycles at -30°C to 80°C, a 15% improvement over previous generations. Finite element analysis (FEA) identifies optimal reinforcement zones, increasing torsional rigidity by 29% for Transit models operating on unpaved roads.

Why Ford Transit Suspension Arm Solutions Dominate

Beyond technical specifications, these components deliver ROI through adaptive compatibility. Recent software updates enable real-time load monitoring via CAN bus integration, alerting drivers to imbalances exceeding 12% threshold. For Focus and Fiesta owners, retrofitting Transit-grade arms requires only minimal hub modifications while doubling service intervals. As regulatory standards evolve toward EU7 emission frameworks, these arms future-proof vehicles against upcoming weight-to-efficiency mandates.

(ford transit suspension arm)

FAQS on ford transit suspension arm

Q: How often should the suspension arm on a Ford Transit be replaced?

A: The Ford Transit suspension arm typically lasts 80,000-100,000 miles. Replace it if you notice uneven tire wear, clunking noises, or poor handling. Always consult a mechanic for an accurate assessment.

Q: What are the symptoms of a faulty Ford Focus front suspension arm?

A: Common signs include steering vibration, misaligned wheels, and knocking sounds over bumps. Ignoring these may damage other suspension components. Prompt inspection is recommended.

Q: Can a Ford Fiesta suspension arm be repaired or must it be replaced?

A: Suspension arms are usually replaced as they’re integral to safety. Bent or cracked arms cannot be safely repaired. Always opt for OEM or high-quality aftermarket replacements.

Q: Are Ford Transit and Ford Focus suspension arms interchangeable?

A: No, suspension arms are model-specific due to weight and design differences. Using incorrect parts risks safety and performance. Verify compatibility using your vehicle’s VIN.

Q: What materials are Ford Transit suspension arms made from?

A: Most are steel or aluminum alloy for durability and weight balance. Aftermarket options may include reinforced materials. Check manufacturer specifications for optimal performance.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English