-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

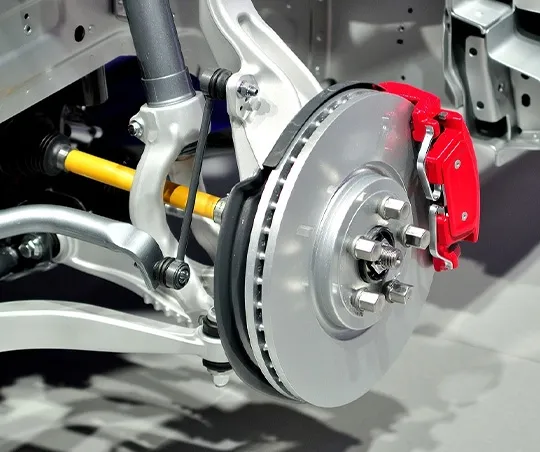

Understanding the Importance of Control Arms in Vehicle Suspension Systems

Understanding the Control Arm in Automotive Engineering

In the realm of automotive engineering, numerous components work in harmony to ensure that a vehicle performs optimally. One critical component in the suspension system is the control arm. Despite its often-overlooked status, the control arm plays a pivotal role in vehicle dynamics, ride quality, and overall safety.

What is a Control Arm?

A control arm is a key part of a vehicle’s suspension system. It connects the chassis of the vehicle to the wheels, allowing for smooth movement and ensuring that the wheels remain properly aligned with the suspension and the road. Typically, control arms are found in pairs an upper control arm and a lower control arm. Each serves specific functions that contribute to the stability and drivability of the vehicle.

Functionality of Control Arms

The primary role of control arms is to manage the movement of the vehicle’s wheels. They facilitate up and down motion, maintaining the wheel’s alignment with the body of the car. This function is crucial, especially when navigating uneven surfaces, as it allows the wheels to respond to bumps while keeping the vehicle stable and balanced. The design of control arms varies between vehicles, with most being triangular in shape, a design that provides strength while allowing for movement.

Moreover, control arms are designed to absorb and dissipate energy generated during driving, particularly during cornering and braking. This energy absorption enhances ride comfort and vehicle handling, helping to reduce the transfer of harsh vibrations to the vehicle’s chassis and occupants.

control arm for car

Types of Control Arms

Control arms come in various forms, including stamped steel, forged steel, and aluminum variants. Stamped steel control arms are commonly used due to their cost-effectiveness and adequate strength. However, forged steel and aluminum control arms often provide enhanced performance benefits like reduced weight and increased rigidity, making them popular choices in performance and luxury vehicles.

There are also adjustable control arms designed for vehicles used in motorsports or for enthusiasts looking to optimize their vehicle’s suspension geometry. These adjustable arms allow for fine-tuning of the camber and caster angles, which can significantly improve handling characteristics.

Maintenance and Issues

Control arms are robust components, but they are not immune to wear and tear. Rubber bushings, which provide pivot points for control arms, can deteriorate over time due to exposure to heat, road grime, and weather conditions. Signs of wear include noise during operation, misalignment, or abnormal tire wear. Regular inspection and maintenance are crucial to address these issues quickly, as deferred maintenance can lead to more severe problems, including compromised handling and safety.

Conclusion

In conclusion, the control arm is a fundamental element of a vehicle's suspension system, playing a vital role in ensuring comfort, stability, and safety. Understanding its function and design can help vehicle owners appreciate the complexity of their automobiles. Regular maintenance of control arms and associated components is essential for optimal vehicle performance. Whether for daily commuting or spirited driving, taking care of your vehicle's suspension system pays dividends in performance and safety on the road.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English