-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

cast steel control arms

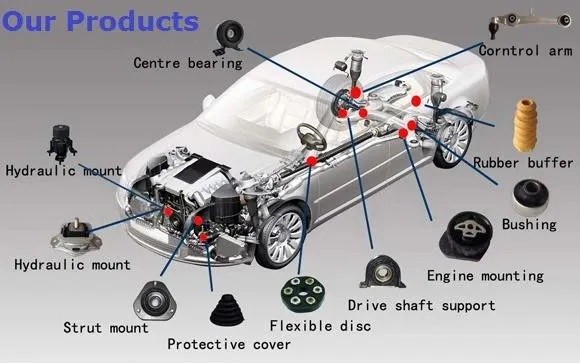

Cast Steel Control Arms An Overview of Manufacturing and Applications

Cast steel control arms are essential components in various applications, ranging from automotive suspension systems to heavy machinery. They are designed to connect different parts of a system while allowing for controlled movement and flexibility. This article delves into the manufacturing process, benefits, and applications of cast steel control arms, highlighting their significance in engineering and industry.

Manufacturing Process

The production of cast steel control arms begins with the selection of high-quality raw materials. Steel is the primary material due to its excellent strength-to-weight ratio and durability. The steel is melted in a furnace and poured into molds that are specifically designed for the control arm's shape. This casting process allows for complex geometries that would be challenging to achieve through traditional machining methods.

Once the molten steel has cooled and solidified, the castings are removed from the molds. The next stage involves cleaning and finishing the surface to eliminate any imperfections. Techniques such as sandblasting or shot peening may be employed to enhance the surface finish, which is critical for ensuring optimal performance and longevity of the control arms.

After surface treatment, the components undergo precision machining. This process includes drilling holes for bolt placements, grinding surfaces to meet specific tolerances, and applying protective coatings. This machining phase is crucial, as it ensures that the control arms fit perfectly in their intended applications and perform optimally under stress.

Benefits of Cast Steel Control Arms

One of the primary advantages of using cast steel for control arms is its outstanding mechanical properties. Cast steel offers excellent tensile strength and toughness, making it capable of withstanding significant force and wear over time. This durability is particularly important in automotive applications, where control arms must endure the stresses of regular driving conditions while maintaining precise alignment and handling.

cast steel control arms

Another benefit is the design flexibility that comes with the casting process. Manufacturers can create intricate designs that accommodate specific functional requirements. For example, control arms may have various shapes, sizes, and thicknesses tailored for particular vehicles or machinery, allowing for customized solutions that meet unique engineering challenges.

Furthermore, cast steel control arms are often cost-effective compared to alternatives such as forged components. The casting process allows for reduced material waste and can be less labor-intensive. This economic efficiency is especially beneficial for manufacturers aiming to produce high volumes of parts without sacrificing quality.

Applications in Various Industries

Cast steel control arms find applications across multiple sectors. In the automotive industry, they play a critical role in the suspension system, connecting the chassis to the wheels and allowing for controlled movement during driving. This connection is vital for vehicle stability and handling, making reliable control arms essential for performance and safety.

Beyond automotive use, cast steel control arms are prevalent in heavy machinery and construction equipment. They contribute to the stability and operational efficiency of machines such as excavators, bulldozers, and cranes. In these contexts, control arms facilitate movement and articulation, allowing operators to perform intricate tasks with precision.

Moreover, cast steel control arms are also utilized in aerospace and rail transport applications. In these highly regulated industries, reliability and performance are paramount. The ability to customize control arms to meet stringent specifications ensures that they perform under the demanding conditions often encountered in aviation and rail systems.

Conclusion

In conclusion, cast steel control arms are a vital component in various industries due to their strength, durability, and design flexibility. The manufacturing process, from casting to machining, ensures that these components meet the specific requirements of their applications. As technology advances and industries evolve, the importance of high-quality control arms will continue to grow, cementing their place as critical elements in modern engineering and manufacturing. Investing in cast steel control arms not only enhances product performance but also contributes to safety and efficiency in multiple applications. As industries strive for innovation, the role of cast steel components remains integral to achieving engineering excellence.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English