-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

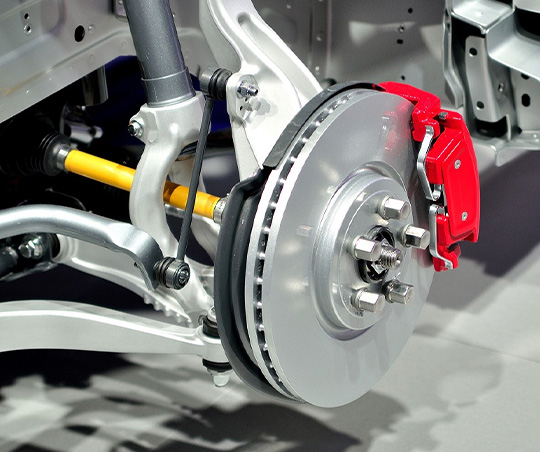

car control arm diagram

Understanding the Control Arm in Automotive Suspension Systems

The automotive suspension system is a critical component of a vehicle, providing comfort and stability during driving. One of the most essential parts of this system is the control arm, often referred to as an A-arm due to its shape. The control arm plays a crucial role in connecting the frame of the vehicle to the wheels, contributing significantly to overall handling characteristics and ride quality.

What is a Control Arm?

The control arm is a hinged link that connects the wheel hub to the vehicle's chassis, allowing for controlled movement of the wheel as it responds to road conditions. There are typically two control arms for each wheel, positioned as upper and lower arms. This design enables the wheel to maintain optimal alignment while absorbing shocks and ensuring a smooth ride.

Functionality of Control Arms

Control arms perform several key functions within the suspension system

1. Wheel Alignment The control arm helps maintain the alignment of the wheels with respect to the vehicle's frame. Proper alignment is vital for even tire wear and optimal handling. Misalignment can lead to poor steering response and reduced fuel efficiency.

2. Absorbing Forces When a vehicle travels over bumps, the suspension system, including the control arms, absorbs the force of impact. This cushioning effect enhances ride comfort and prevents excessive stress on the vehicle's structure.

3. Allowing Movement Control arms allow for vertical movement of the wheels, enabling them to rise and fall with the terrain. This mobility is essential for maintaining tire contact with the road surface, which is crucial for traction and braking.

4. Supporting Weight Control arms also support the weight of the vehicle. They must be constructed from strong, durable materials to withstand the considerable stresses experienced during driving, especially in off-road or high-performance conditions.

car control arm diagram

Types of Control Arms

Control arms come in various designs. The most common types include

- Tubular Control Arms These are lightweight and often used in performance vehicles. Their design allows for reduced weight without sacrificing strength.

- Stamped Control Arms These are made from a flat sheet of metal that is stamped into shape. They are commonly found in many everyday vehicles due to their cost-effectiveness and ease of manufacturing.

- Adjustable Control Arms These allow for fine-tuning of suspension geometry, making them ideal for vehicles modified for specific performance needs.

Maintenance and Common Issues

Like all automotive components, control arms require maintenance to ensure optimal performance. Common issues include worn bushings and joints, which can lead to clunking noises, poor handling, and uneven tire wear. Regular inspections and timely replacements of these components can extend the lifespan of the control arms and contribute to overall vehicle safety.

Conclusion

The control arm is a vital component of the automotive suspension system, offering stability, comfort, and aesthetics. A deeper understanding of how control arms function and their impact on vehicle dynamics can help car owners appreciate the engineering that goes into making their driving experience safe and enjoyable. Whether navigating city streets or tackling rugged terrain, the control arm plays an indispensable role in maintaining the connection between the vehicle and the road. By being aware of its importance and ensuring regular maintenance, drivers can enhance their vehicle's performance and extend its lifespan.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English