-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

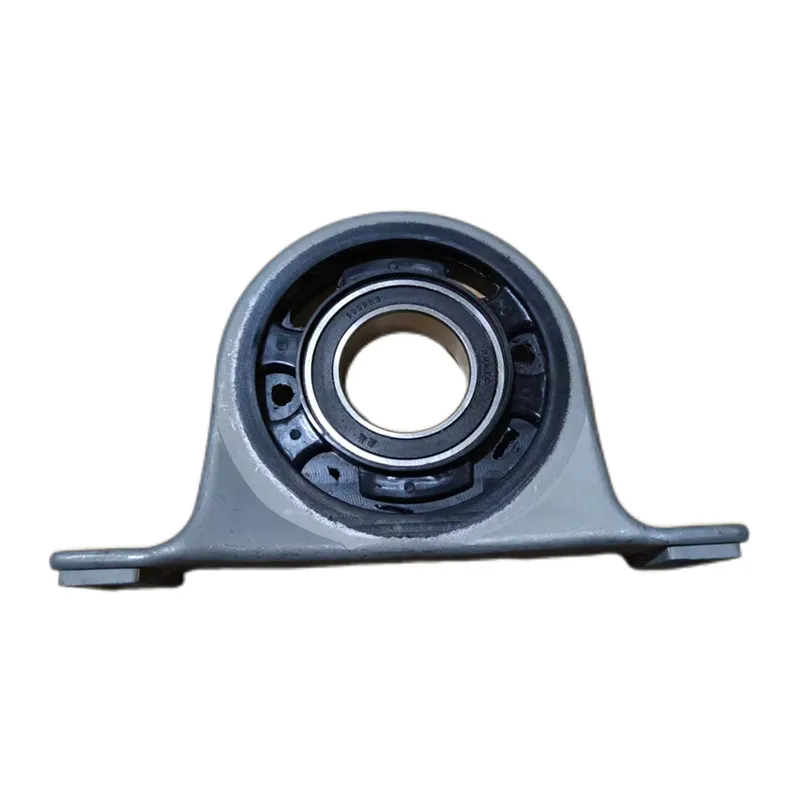

car control arm bushing

Understanding Car Control Arm Bushings Importance and Maintenance

Control arm bushings play a crucial role in a vehicle’s suspension system, significantly affecting ride quality, handling, and overall vehicle performance. Though often overlooked, these rubber or polyurethane components are essential for connecting the control arm to the chassis, providing a pivot point that allows for smooth suspension movement while absorbing road impacts. Understanding their function, signs of wear, and maintenance can help ensure a smooth and safe driving experience.

What Are Control Arm Bushings?

Control arm bushings are cylindrical components made of rubber or polyurethane that serve as dampers between metal parts in the suspension system. They are located on the control arms, which are responsible for connecting the wheel hub to the vehicle’s chassis. By allowing controlled movement, bushings help to maintain proper wheel alignment and prevent excessive wear on other suspension components.

The control arms themselves can be of various designs depending on the make and model of the vehicle; however, they all rely on bushings to function effectively. The materials used in bushings can vary, with rubber being the most common due to its flexibility and cost-effectiveness. However, polyurethane bushings are increasingly popular for performance applications due to their enhanced durability and performance characteristics.

Signs of Worn Control Arm Bushings

As with any automotive component, control arm bushings experience wear over time

. Signs of wear can manifest in several ways1. Clunking or Rattling Noise One of the most common indicators of worn bushings is a noise coming from the suspension when driving over bumps or uneven surfaces. This noise often signifies that the bushings have degraded and can no longer effectively dampen vibration and noise.

2. Poor Handling or Steering Response Worn bushings can lead to compromised handling. Drivers may notice that their vehicle feels loose or unstable, especially during cornering. This is due to the loss of connection between the control arm and the chassis.

car control arm bushing

3. Uneven Tire Wear Another significant sign of bushing wear is uneven tire wear patterns. If the control arm is not positioned correctly due to degraded bushings, it can cause tires to wear more on one side than another.

4. Visual Inspection Sometimes, visual inspection can reveal cracked or torn bushings. If the rubber is severely cracked or if there are noticeable gaps, it is a clear sign that replacement is necessary.

Maintenance and Replacement

Maintaining control arm bushings can extend their life and improve vehicle performance. Regular inspections should be part of routine maintenance, particularly during tire rotations or alignment checks. If any signs of wear are present, it is prudent to address them promptly to avoid more severe suspension issues.

When it comes to replacement, it’s essential to choose high-quality bushings. While standard rubber bushings can suffice for everyday vehicles, those seeking improved performance may consider upgrading to polyurethane options. These provide better handling, longevity, and resistance to environmental factors.

If you are unsure about the condition of your vehicle’s control arm bushings, consult a professional mechanic for a thorough inspection. They can provide expert advice on necessary repairs and help in choosing the right materials for replacements.

Conclusion

Control arm bushings may seem like small components, but their importance in vehicle dynamics cannot be understated. By understanding their function and keeping an eye out for signs of wear, drivers can ensure a safer, more comfortable driving experience. Regular maintenance and timely replacements will not only enhance vehicle performance but also prolong the lifespan of other suspension components, making them a worthy investment for any car owner.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English