-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

carbon fiber control arms

The Rise of Carbon Fiber Control Arms in Automotive Engineering

In the quest for lightweight yet strong materials, the automotive industry has been increasingly turning to carbon fiber, particularly in the development of control arms. Control arms are a critical component of a vehicle's suspension system, linking the chassis to the wheels and allowing for smooth handling and responsive steering. The shift to carbon fiber in this area not only promises enhanced performance but also significantly contributes to overall vehicle efficiency.

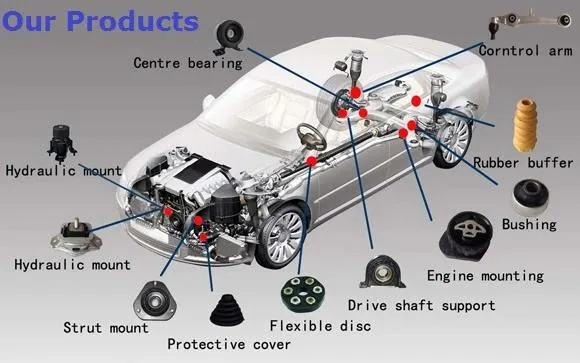

Understanding Control Arms

Control arms play a vital role in maintaining the stability and handling characteristics of a vehicle. They are designed to pivot on a single axis, allowing the wheels to move up and down while keeping them properly aligned with the chassis. Traditionally, control arms have been made from heavy materials like steel or aluminum; however, as automotive technology evolves, the need for weight reduction without compromising strength has become paramount.

Carbon Fiber A Superior Alternative

Carbon fiber is a composite material made from thin, strong crystalline filaments of carbon. It is renowned for its exceptional strength-to-weight ratio. Compared to steel, carbon fiber is significantly lighter, which translates to improved fuel efficiency and performance due to reduced mass. In addition to being lightweight, carbon fiber possesses remarkable stiffness and resilience, making it ideal for components subjected to constant stress and strain, such as control arms.

The use of carbon fiber control arms offers substantial benefits. Enhanced agility and responsiveness can be achieved as a result of the weight savings, allowing vehicles to accelerate faster, handle sharper turns, and exhibit improved braking performance. Additionally, the damping characteristics of carbon fiber can lead to a smoother ride, as it mitigates vibrations and shocks that would otherwise be transmitted to the cabin.

Applications in Motorsports and Consumer Vehicles

carbon fiber control arms

The advantages of carbon fiber control arms have been recognized in high-performance vehicles, particularly in motorsport applications where every ounce of weight matters. Racing teams have integrated carbon fiber components to shave milliseconds off lap times, gaining a competitive edge. As technology has progressed, the adoption of carbon fiber in consumer vehicles has also started to gain traction. High-end sports cars and luxury vehicles are increasingly showcasing carbon fiber parts, reflecting both performance enhancements and a premium aesthetic appeal.

For example, manufacturers like Lamborghini and McLaren have made extensive use of carbon fiber in their suspension systems, which not only improves performance but also adds a visually striking element to the vehicle’s design. Moreover, mainstream automakers are beginning to offer carbon fiber options as part of their performance packages, allowing customers to experience the benefits previously reserved for elite racing machines.

Challenges and Considerations

Despite its many advantages, the implementation of carbon fiber control arms is not without challenges. The cost of carbon fiber production is significantly higher than that of traditional materials, which can impact the overall vehicle pricing. Additionally, the manufacturing processes involved in creating carbon fiber components are more complex and time-consuming. Lastly, while carbon fiber is incredibly strong, it is also susceptible to certain types of impact damage, which necessitates careful engineering and design considerations to mitigate potential weaknesses.

The Future of Carbon Fiber in Automotive Engineering

Looking ahead, the future of carbon fiber control arms appears promising. As production techniques continue to evolve and costs decrease, more manufacturers may incorporate this innovative material into their vehicle designs. Advances in recycling methods and improved manufacturing processes may also address some of the sustainability concerns associated with carbon fiber.

In conclusion, the adoption of carbon fiber control arms represents a significant advancement in automotive engineering. The benefits of reduced weight, increased strength, and improved ride quality position carbon fiber as a game-changer in the industry. As the automotive landscape evolves, this lightweight material could revolutionize not only control arms but various other components, paving the way for more efficient, high-performance vehicles that meet the demands of modern consumers. The integration of carbon fiber technology signifies a step towards the future of automotive innovation—one where efficiency, performance, and sustainability coexist.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English