-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

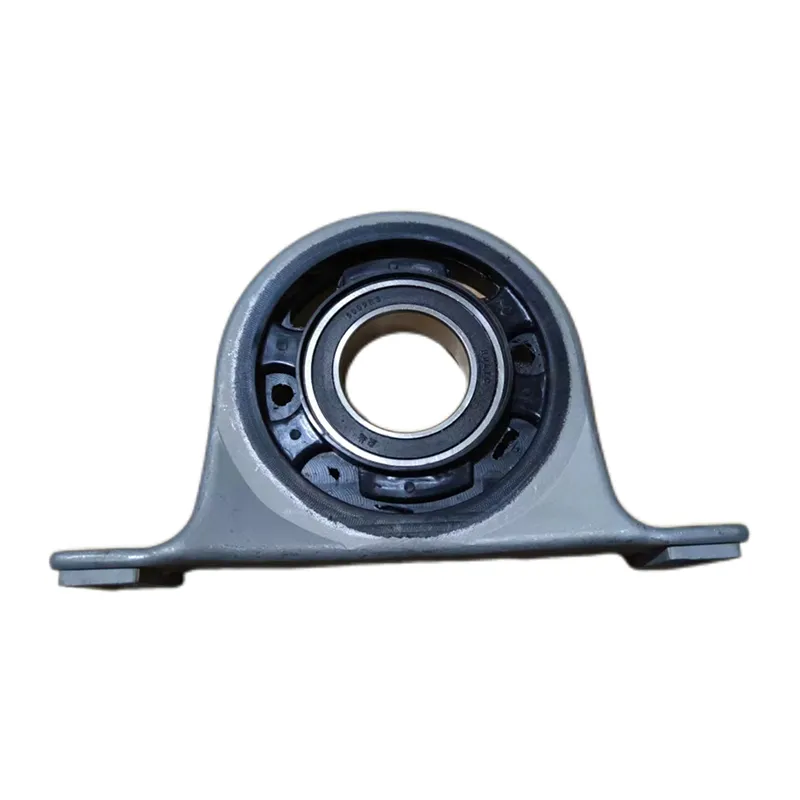

bracket bearing support for drive shaft

Understanding Bracket Bearing Support for Drive Shafts

In the realm of mechanical engineering, the bracket bearing support for drive shafts plays a pivotal role in the performance and longevity of various machines and vehicles. As integral components of a drivetrain system, these supports provide the essential stability and alignment needed for efficient operation. This article delves into the significance of bracket bearing supports, their types, installation considerations, and common applications.

What is a Bracket Bearing Support?

A bracket bearing support is a structural component designed to hold and support rotating shafts within machinery. It consists of a rigid bracket that is typically mounted to a frame or body, incorporating bearings that allow the shaft to rotate smoothly with minimal friction. The primary function of this support system is to maintain the alignment of the drive shaft, ensuring that power is transmitted effectively from one component to another, whether it be from an engine to a transmission or from a motor to a load.

Importance of Bracket Bearing Supports

Properly designed and installed bracket bearing supports are crucial for maintaining the overall integrity of a mechanical system. The key benefits include

1. Vibration Reduction By providing stable support for the drive shaft, bracket bearings help minimize vibrations that can lead to premature wear and tear of components.

2. Alignment Maintenance Maintaining the correct alignment of a drive shaft is essential for reducing stress on both the shaft and attached components. Misalignment can result in increased backlash, noise, and even catastrophic failure.

3. Load Distribution These supports help distribute loads evenly across the drive shaft, preventing localized stresses that could cause deformation or breakage.

4. Facilitating Maintenance Well-placed bracket bearing supports make it easier to access drive shafts for maintenance tasks, such as lubrication or inspections, thereby enhancing the lifespan of the equipment.

Types of Bracket Bearing Supports

There are various types of bracket bearing supports designed to accommodate different applications

1. Flanged Bearing Supports This type features a flange that allows for easy mounting to a fixed surface. Flanged bearings are widely used in automotive and industrial applications.

bracket bearing support for drive shaft

2. Pillow Block Bearings These are mounted in a block and offer support for a shaft, allowing for easy maintenance and replacement. They are commonly used in conveyors, fans, and other machinery.

3. Take-Up Bearings Designed for applications where shaft length can change due to thermal expansion or other factors, take-up bearings allow for adjustments to maintain the correct tension and alignment.

4. Spherical Bearings These bearings can accommodate angular misalignments, providing a degree of flexibility in applications where absolute alignment is challenging.

Installation Considerations

When installing bracket bearing supports, several factors must be taken into account

1. Material Selection The choice of materials for both the bracket and bearings will affect durability and performance. Common materials include steel, aluminum, and various composite materials.

2. Load Capacity It is crucial to select supports that can handle the expected loads. Underestimating load requirements can lead to equipment failure.

3. Environmental Factors Conditions such as temperature, moisture, and exposure to chemicals can affect the choice of bearings and the overall design of the support.

4. Maintenance Access Ensure that there is adequate space available for maintenance tasks without compromising the overall design of the machinery.

Applications of Bracket Bearing Supports

Bracket bearing supports find application across a wide range of industries. In automotive engineering, they are integral to the drivetrain, supporting the driveshaft and ensuring smooth power transfer. In manufacturing and industrial machinery, they provide the necessary support for conveyor belts, fans, and rotating mechanisms, enhancing efficiency and reliability.

In conclusion, the bracket bearing support for drive shafts is an essential component that contributes significantly to the performance and durability of machinery. By understanding the types, functions, and considerations associated with these supports, engineers can better design systems that are robust, efficient, and easy to maintain, ultimately leading to improved operational success and reduced downtime. Whether in vehicles or industrial machines, the importance of these structures cannot be overstated, as they form the backbone of effective power transmission systems.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English