-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

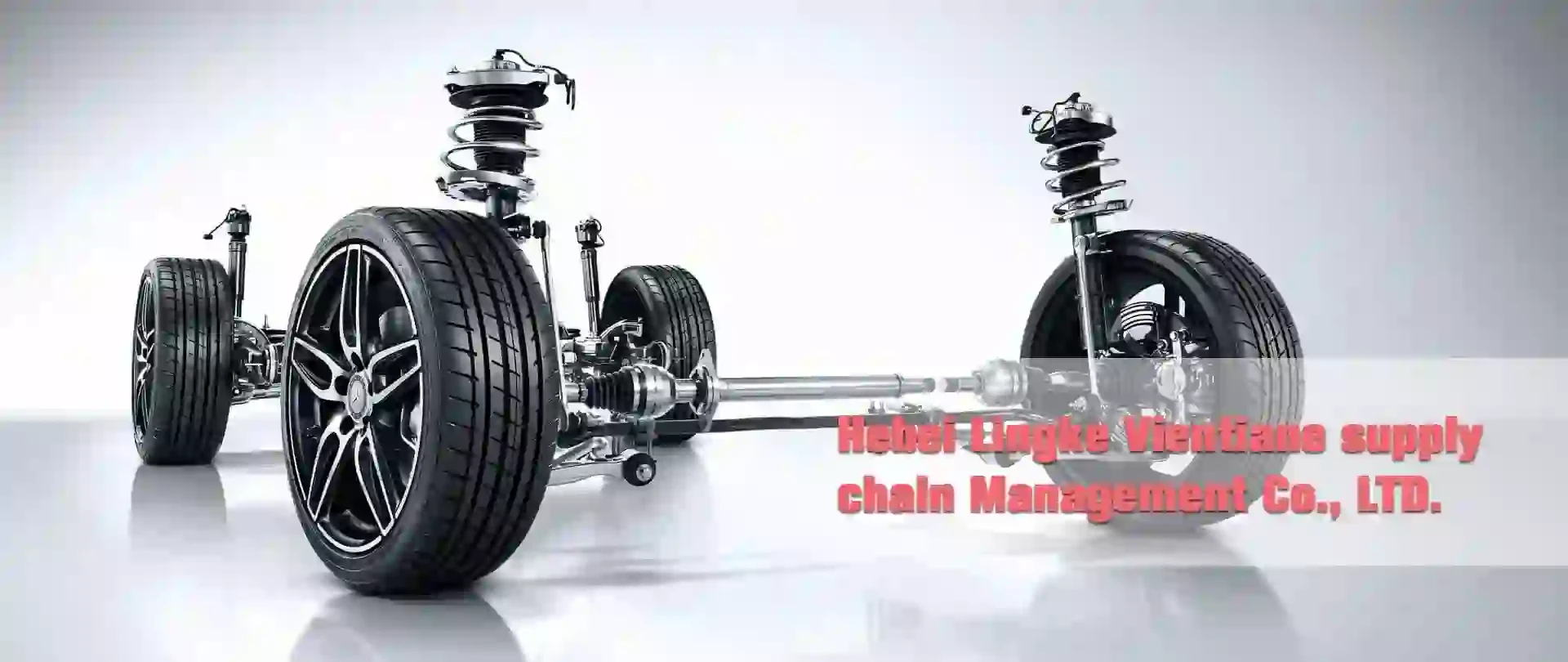

Understanding the Role of Axle Control Arms in Vehicle Suspension Systems

Understanding the Importance of Axle Control Arms in Automotive Suspension Systems

The axle control arm is a crucial component in the suspension systems of vehicles, playing a significant role in ensuring stability, safety, and comfort during driving. This article delves into the functionality and importance of axle control arms, their design, materials, and the implications of neglecting their maintenance.

What Are Axle Control Arms?

Axle control arms, also known simply as control arms, are part of the vehicle's suspension geometry. Their primary function is to connect the vehicle's chassis to the axle, allowing for proper wheel alignment and movement. Control arms are typically designed as either upper or lower arms and come in various shapes, depending on the vehicle type and suspension design.

Functionality of Control Arms

Control arms serve multiple vital purposes within the suspension system

1. Wheel Control They help maintain the correct position of the wheels relative to the chassis, ensuring that the wheels can move up and down as the vehicle traverses bumps and dips in the road. This movement is essential for providing a comfortable ride and maintaining traction.

2. Camber and Caster Angles Control arms help manage camber and caster angles, which are critical to vehicle handling. Proper angles improve tire contact with the road, enhancing cornering stability and tire wear.

3. Load Distribution They facilitate the even distribution of weight and forces across the suspension components. This load distribution is vital for vehicle stability, particularly during maneuvers such as cornering, braking, and accelerating.

Design and Materials

Axle control arms can be found in various designs, including stamped steel, tubular, and forged aluminum. Each design and material has its benefits and drawbacks

axle control arm

- Stamped Steel This is a common and cost-effective option that offers good strength. However, they may be heavier than other materials, affecting performance and fuel efficiency.

- Tubular Control Arms These are lighter and can provide higher strength-to-weight ratios. Tubular designs also offer greater resistance to bending and twisting forces, making them suitable for high-performance vehicles.

- Forged Aluminum While more expensive, forged aluminum control arms provide excellent strength, reduced weight, and resistance to corrosion.

Maintenance and Care

Like all automotive components, axle control arms experience wear and tear over time. Neglecting their maintenance can lead to several issues

1. Alignment Problems Worn control arms can cause misalignment, leading to uneven tire wear and poor handling. Drivers may notice that their vehicle pulls to one side or requires constant steering corrections.

2. Increased Wear on Other Components Damaged or worn control arms can place additional stress on other suspension components, resulting in a cascade of failures that can be costly to repair.

3. Safety Risks A failing control arm can severely compromise vehicle stability, increasing the risk of accidents, especially during high-speed maneuvers or emergency braking situations.

Conclusion

Axle control arms are essential for maintaining the integrity of a vehicle's suspension system. Understanding their role, design, and maintenance needs can help drivers ensure their vehicles remain safe and operate correctly. Regular inspections and timely replacements of worn or damaged control arms are crucial for extending the lifespan of the suspension system and enhancing overall driving safety.

In summary, while often overlooked, axle control arms are a foundational element of automotive engineering that plays a critical role in performance, safety, and comfort on the road. Whether for daily commuters or high-performance vehicles, maintaining the integrity of control arms is paramount. Proper care can enhance vehicle longevity and provide a superior driving experience.

-

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

English

English