-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Types of Control Arms in Automotive Suspension Systems Explained

Understanding Control Arm Types in Automotive Suspension Systems

Control arms are essential components of vehicle suspension systems, serving as links between the vehicle chassis and its wheels. They play a crucial role in maintaining vehicle stability, handling, and ride quality by allowing for the controlled movement of the suspension while minimizing vibrations and impacts from the road. There are various types of control arms, each designed with specific applications and mechanical properties in mind. This article aims to provide a comprehensive overview of the different control arm types and their significance in automotive engineering.

1. Upper and Lower Control Arms

Control arms are typically categorized into two primary types upper control arms (UCA) and lower control arms (LCA). In most vehicles, the suspension system features both.

Upper Control Arms (UCA) Positioned above the wheel, upper control arms help control the angles of the wheel during movement. They are crucial for establishing camber angles—which affect tire wear and handling—particularly in MacPherson strut setups commonly found in front-wheel-drive vehicles.

Lower Control Arms (LCA) Located below the wheel, lower control arms are integral to supporting the weight of the vehicle and facilitating vertical wheel movement. They often handle more load and forces than UCAs, making them essential for the vehicle's overall stability.

2. Short and Long Control Arms

Control arms can also be classified as short or long based on their design and function.

Short Control Arms These provide a more compact design and are often used in performance applications where handling is prioritized. The shorter length can improve the suspension's roll centers and help control the vehicle’s response to various driving conditions, making them popular in racing and high-performance cars.

Long Control Arms Longer control arms are typically favored for better ride quality and comfort. They allow for greater wheel travel and can enhance the geometry of the suspension, leading to improved traction and stability over uneven surfaces. This design is often seen in larger vehicles and SUVs designed for comfort.

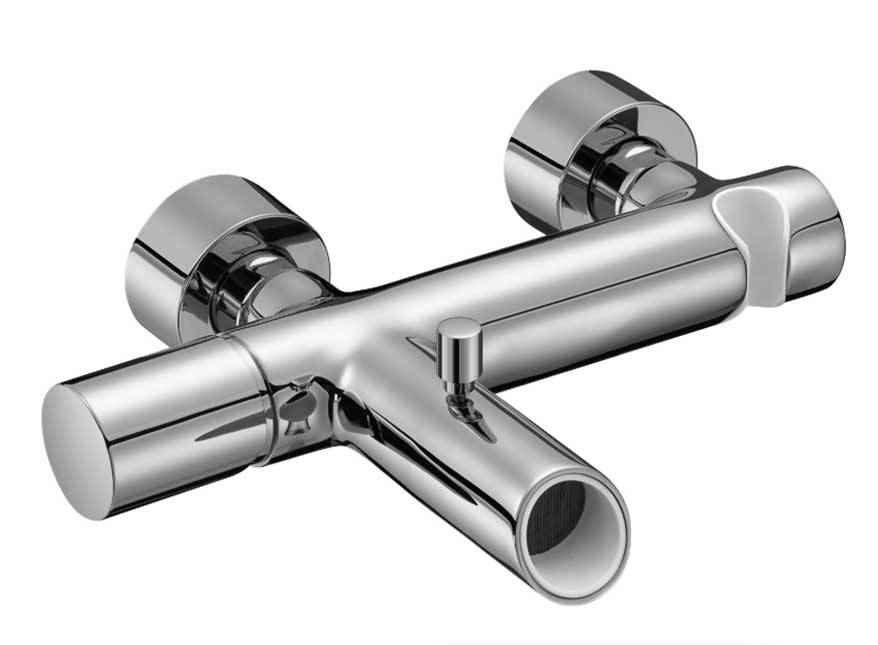

control arm types

3. Fixed vs. Adjustable Control Arms

Control arms can also differ in their adjustability, leading to a distinction between fixed and adjustable types.

Fixed Control Arms These are standard, non-adjustable arms that are set to specific geometry parameters during manufacturing. They provide good handling and stability for most applications but lack the flexibility to fine-tune suspension settings for specific driving conditions or personal preferences.

Adjustable Control Arms These have provisions for modifications, allowing users to alter the geometry according to their requirements. For example, adjustable control arms can enable changes in camber and caster settings, which are critical for performance tuning, especially in motorsport environments.

4. Materials Used in Control Arms

Another important aspect of control arms is the materials used in their construction. Traditional control arms are often made from stamped steel, which provides a good balance between strength, weight, and cost. However, innovations in automotive engineering have led to the use of alternative materials

Aluminum Control Arms Many performance-oriented vehicles now use aluminum control arms due to their lighter weight and resistance to corrosion. While they tend to be more expensive, the reduced weight can lead to improved fuel efficiency and enhanced handling.

Composite Control Arms Emerging technologies have introduced composite materials, which provide excellent weight savings and flexibility. These materials can absorb vibrational energy, further enhancing ride quality.

Conclusion

Control arms are a fundamental aspect of modern vehicle suspension systems, impacting not only how a vehicle handles but also its overall performance and comfort. Understanding the various types—upper and lower, short and long, fixed and adjustable—along with the materials used in their construction is essential for automotive enthusiasts, engineers, and manufacturers alike. As technology evolves, so too do the designs and capabilities of control arms, paving the way for more advanced and efficient suspension systems that enhance both safety and enjoyment in driving.

-

English

English

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

Italian

Italian