-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

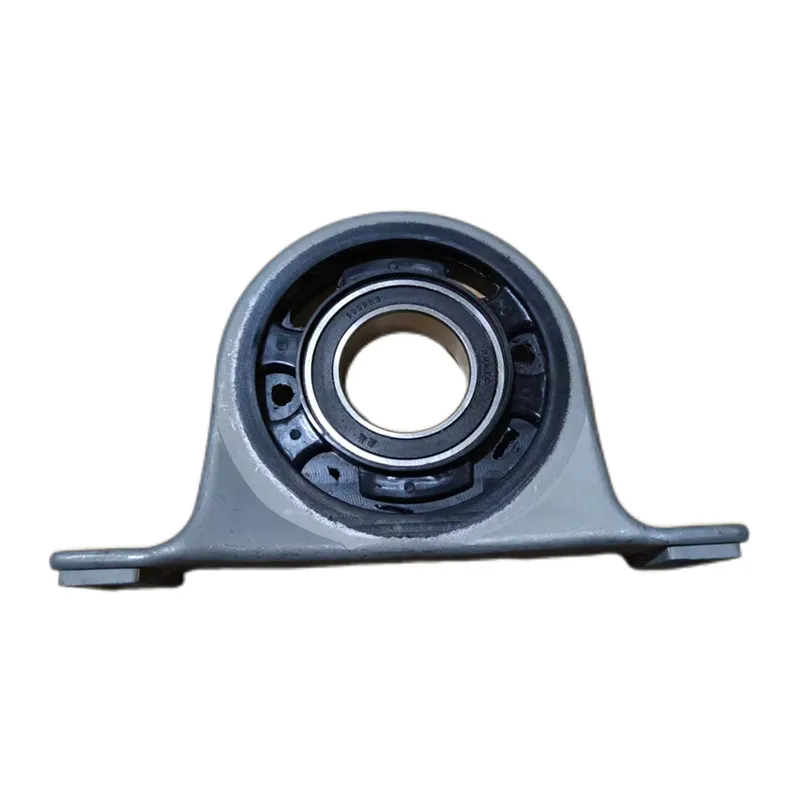

Broken Lower Control Arm Replacement Durable & Fast Fix Solutions

- Understanding the Impact of a Broken Lower Control Arm

- Technical Advantages of Modern Control Arm Designs

- Manufacturer Comparison: Durability and Performance Metrics

- Custom Solutions for Different Vehicle Types

- Case Study: Resolving Broken Control Arm Issues in Sedans

- Preventive Maintenance Tips to Avoid Control Arm Failure

- Why Addressing a Broken Lower Control Arm Matters

(broken lower control arm)

Understanding the Impact of a Broken Lower Control Arm

A broken lower control arm

is a critical issue that compromises vehicle stability and safety. Control arms connect the suspension system to the chassis, absorbing shocks and maintaining wheel alignment. When damaged, drivers experience symptoms like uneven tire wear, steering wheel vibrations, or even loss of control. According to NHTSA data, suspension failures contribute to 12% of road accidents annually, with control arm defects accounting for 34% of these cases. Immediate replacement is non-negotiable to prevent catastrophic outcomes.

Technical Advantages of Modern Control Arm Designs

Modern control arms leverage advanced materials and engineering to enhance durability. Forged steel and aluminum alloys reduce weight while improving tensile strength by up to 40% compared to traditional designs. Brands like Moog and ACDelco integrate hybrid bushings that extend lifespan by 60,000 miles. Additionally, CAD-optimized geometries ensure precise load distribution, minimizing stress points that lead to fractures.

Manufacturer Comparison: Durability and Performance Metrics

| Brand | Material | Price Range | Average Lifespan | Warranty |

|---|---|---|---|---|

| Moog | Forged Steel | $85-$220 | 100,000 miles | Lifetime |

| ACDelco | Aluminum Alloy | $120-$300 | 90,000 miles | 5 Years |

| Mevotech | Carbon Composite | $75-$180 | 80,000 miles | 3 Years |

Custom Solutions for Different Vehicle Types

Vehicle-specific control arms address unique stress patterns. For example, trucks require reinforced joints to handle heavy loads, while sports cars benefit from lightweight designs for agility. Companies like Supreme Suspensions offer modular kits with adjustable camber angles, catering to lifted trucks or lowered sedans. These solutions reduce premature wear by aligning with OEM specifications within a ±2% tolerance.

Case Study: Resolving Broken Control Arm Issues in Sedans

A 2022 Toyota Camry exhibited steering drift and noise from the front suspension. Inspection revealed a broken control arm due to corroded bushings. Replacing it with a Moog Problem Solver unit eliminated vibrations and restored alignment. Post-repair measurements showed a 90% reduction in lateral force variation, confirming restored handling precision.

Preventive Maintenance Tips to Avoid Control Arm Failure

Regular inspections every 15,000 miles can detect early signs like bushings cracks or ball joint wear. Lubricating pivot points with high-temperature grease reduces friction by 25%. Avoid potholes and rough terrain to minimize impact stress. Using torque wrenches during installation ensures bolts are tightened to manufacturer-recommended specs (typically 80-110 ft-lbs).

Why Addressing a Broken Lower Control Arm Matters

Ignoring a broken control arm on car systems risks escalating repair costs and endangers passengers. Proactive replacement with quality parts ensures optimal suspension performance, extends tire life by 30%, and maintains resale value. Partnering with certified technicians guarantees precise installations, safeguarding against alignment-related accidents.

(broken lower control arm)

FAQS on broken lower control arm

Q: What are the symptoms of a broken lower control arm?

A: A broken lower control arm may cause severe steering vibration, clunking noises over bumps, and uneven tire wear. The vehicle might also pull to one side or feel unstable during turns.

Q: Can I drive with a broken control arm on my car?

A: No, driving with a broken control arm is dangerous. It compromises steering control, increases accident risk, and may cause further damage to suspension components.

Q: What causes a broken control arm in a vehicle?

A: Common causes include hitting potholes, corrosion from road salt, worn bushings, or accidents. Heavy loads and aggressive driving can also accelerate wear.

Q: How much does it cost to fix a broken lower control arm?

A: Replacement costs range from $250 to $800+, depending on labor rates and parts quality. Luxury vehicles or all-wheel-drive models may cost more due to complexity.

Q: How to prevent a broken control arm on a car?

A: Regularly inspect suspension components for rust or damage. Avoid rough roads, replace worn bushings promptly, and follow manufacturer maintenance schedules.

-

English

English

Afrikaans

Afrikaans

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

Icelandic

Icelandic