-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 16, 2025 00:34

Back to list

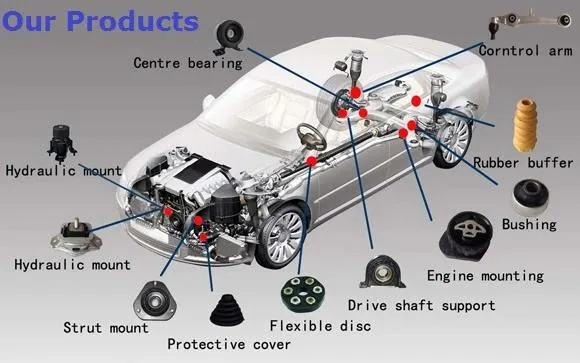

China manufacturer production center support bearing drive shaft bearing 9064100281 drive shaft support

Experiencing a broken lower control arm can be alarming, but understanding the issue and how to address it can make all the difference. Lower control arms are crucial components in a vehicle's suspension system, serving as the link between the suspension and the vehicle's frame. When this component breaks, it affects your ability to steer and maintain vehicle stability, posing serious safety hazards.

The installation process of a new lower control arm requires specialized tools and expertise. Professionals caution against DIY attempts unless one has considerable mechanical experience because improper installation can lead to further damage or safety issues. Instead, seeking the assistance of certified technicians ensures that the replacement is handled correctly, followed by a wheel alignment to guarantee proper vehicle handling. Trustworthiness in service is paramount, especially when dealing with such a critical vehicle component. Choosing a reputable repair shop with ASE-certified mechanics can provide peace of mind. These certifications indicate a high level of automotive service excellence and adherence to industry standards. In addition to repair, understanding regular maintenance and inspection of suspension components can prevent future problems. Routine checks can identify wear and tear early, allowing for proactive solutions rather than reactive repairs. It's recommended to have the entire suspension system inspected at least once a year or every 12,000 miles to keep everything functioning optimally. Ultimately, addressing a broken lower control arm promptly not only restores the vehicle's safety and functionality but also prolongs its life. Educating oneself about the vehicle's suspension system and adhering to regular maintenance schedules can mitigate risks and lead to more informed decisions regarding automotive care.

The installation process of a new lower control arm requires specialized tools and expertise. Professionals caution against DIY attempts unless one has considerable mechanical experience because improper installation can lead to further damage or safety issues. Instead, seeking the assistance of certified technicians ensures that the replacement is handled correctly, followed by a wheel alignment to guarantee proper vehicle handling. Trustworthiness in service is paramount, especially when dealing with such a critical vehicle component. Choosing a reputable repair shop with ASE-certified mechanics can provide peace of mind. These certifications indicate a high level of automotive service excellence and adherence to industry standards. In addition to repair, understanding regular maintenance and inspection of suspension components can prevent future problems. Routine checks can identify wear and tear early, allowing for proactive solutions rather than reactive repairs. It's recommended to have the entire suspension system inspected at least once a year or every 12,000 miles to keep everything functioning optimally. Ultimately, addressing a broken lower control arm promptly not only restores the vehicle's safety and functionality but also prolongs its life. Educating oneself about the vehicle's suspension system and adhering to regular maintenance schedules can mitigate risks and lead to more informed decisions regarding automotive care.

Latest news

Unbeatable Control Arm Wholesale Deals Varieties

NewsJul.25,2025

Trusted Front Lower Control Arm Manufacturing Solutions

NewsJul.25,2025

Superior Car Control Arms for Advanced Auto Parts

NewsJul.25,2025

Mastering Car Performance with Supreme Front Control Arms

NewsJul.25,2025

Extended Control Arms: Revolutionizing Suspension Performance

NewsJul.25,2025

Control Arm Advance Auto Parts: Essential Components for Vehicle Performance

NewsJul.25,2025

-

English

English

Albanian

Albanian

Amharic

Amharic

Arabic

Arabic

Armenian

Armenian

Azerbaijani

Azerbaijani

Basque

Basque

Belarusian

Belarusian

Bengali

Bengali

Bosnian

Bosnian

Bulgarian

Bulgarian

Catalan

Catalan

Cebuano

Cebuano

Corsican

Corsican

Croatian

Croatian

Czech

Czech

Danish

Danish

Dutch

Dutch

Esperanto

Esperanto

Estonian

Estonian

Finnish

Finnish

French

French

Frisian

Frisian

Galician

Galician

Georgian

Georgian

German

German

Greek

Greek

Gujarati

Gujarati

Haitian Creole

Haitian Creole

Hausa

Hausa

Hawaiian

Hawaiian

Hebrew

Hebrew

Hindi

Hindi

Miao

Miao

Hungarian

Hungarian

Icelandic

Icelandic

Igbo

Igbo

Indonesian

Indonesian

Irish

Irish

Italian

Italian

Japanese

Japanese

Javanese

Javanese

Kannada

Kannada

Kazakh

Kazakh

Khmer

Khmer

Rwandese

Rwandese

Korean

Korean

Kurdish

Kurdish

Kyrgyz

Kyrgyz

Lao

Lao

Latin

Latin

Latvian

Latvian

Lithuanian

Lithuanian

Luxembourgish

Luxembourgish

Macedonian

Macedonian

Malgashi

Malgashi

Malay

Malay

Malayalam

Malayalam

Maltese

Maltese

Maori

Maori

Marathi

Marathi

Mongolian

Mongolian

Myanmar

Myanmar

Nepali

Nepali

Norwegian

Norwegian

Norwegian

Norwegian

Occitan

Occitan

Pashto

Pashto

Persian

Persian

Polish

Polish

Portuguese

Portuguese

Punjabi

Punjabi

Romanian

Romanian

Russian

Russian

Samoan

Samoan

Scottish Gaelic

Scottish Gaelic

Serbian

Serbian

Sesotho

Sesotho

Shona

Shona

Sindhi

Sindhi

Sinhala

Sinhala

Slovak

Slovak

Slovenian

Slovenian

Somali

Somali

Spanish

Spanish

Sundanese

Sundanese

Swahili

Swahili

Swedish

Swedish

Tagalog

Tagalog

Tajik

Tajik

Tamil

Tamil

Tatar

Tatar

Telugu

Telugu

Thai

Thai

Turkish

Turkish

Turkmen

Turkmen

Ukrainian

Ukrainian

Urdu

Urdu

Uighur

Uighur

Uzbek

Uzbek

Vietnamese

Vietnamese

Welsh

Welsh

Bantu

Bantu

Yiddish

Yiddish

Yoruba

Yoruba

Zulu

Zulu

Afrikaans

Afrikaans